Tower Components and accessories

We design each and every part of the Tower Solutions ERS System with meticulous attention to detail. One of the many things that sets Tower Solutions apart from our competitors is our towers’ ability to be configured and used in endless ways.

Our wide array of tower components allow our ERS systems to be used safely and confidently in places most towers would fail. If you have challenging terrain to overcome, Tower Solutions has the answer to your problem.

TOWER Components

Base Plate

(Foundation Plate)

The foundation plate is designed to support the fully loaded tower, distributing its weight evenly to the ground. This plate is placed directly on the ground and fixed using four steel pinning rods installed in the corners of the plate. No other foundation structure is required.

The plate has a small footprint of 4ft x 4ft (1.2m x 1.2m), and has a flange for attaching the articulation component.

A handle in each corner makes for easy handling.

When selecting a spot to erect the tower, the entire plate should make contact with the ground. Rocky or uneven soil must be smoothed to give a flat surface. Soft or wet ground needs to be assessed to determine the minimum surface area required for the foundation plate, and if necessary, Tower Solutions’ extension plates can be used to give a larger surface contact for better load bearing capacity.

The foundation plate does not need to be on level ground. It can be installed on a slope up to 30 degrees if necessary.

Material: Aluminum Alloy 6061-T6

Weight: 76.7 kg

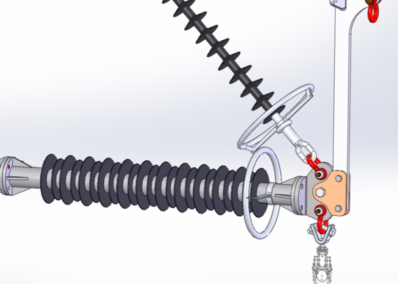

Articulation

The articulation consists of a fixed steel cone and a pivoting aluminum plate. The cone is mounted to the flange on the foundation plate and is fitted with a steel ball that connects with the pivoting plate. The pivoting plate connects the tower to the foundation. The pivoting plate has a proprietary weight-bearing surface made of a special bronze alloy that reduces friction to a minimum and eliminates corrosion. This prevents wearing of the galvanizing finish and provides an optimum surface for a weight bearing contact point.

The low friction properties of the bearing surface means that the tower is always free to move, so that the tower does not need to bend even with small movements. This enables the tower to hold much greater weights. The pivoting motion allows full freedom of movement in every direction, a feature that not only makes the tower very easy to erect, but also enables it to distribute load evenly at all times.

The pivoting ability of the tower means that it can be erected without having to line up the tower with the direction of the overhead conductors. The base can be positioned to suit ground conditions, even on inclined terrain if necessary, because the tower’s ability to rotate makes it adjustable to any direction.

The articulation is easy to assemble. Attachment blocks welded to the sides of the cone are used to accommodate threaded rods that support the pivoting plate during transport and storage. These blocks also make a handy step for the line worker for beginning the climb up the tower.

Material: G40.21-44W Galvanized steel, Bronze Alloy C954, Aluminum Alloy 6061-T6

Weight of articulation cone: 61 kg

Weight after assembly with top plate: 116 kg

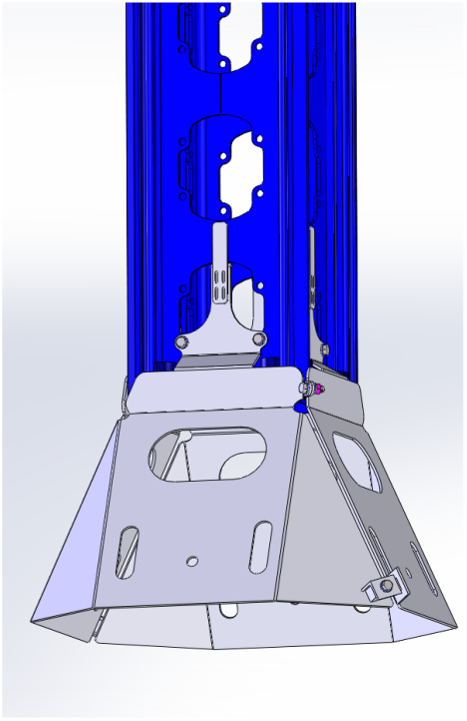

Tower Section

The tower section is carefully designed, with meticulous attention paid to every detail and dimension. Each tower section is fabricated as an extruded rectangular cross-section, with uniformly spaced openings on all four sides. These openings serve a number of purposes, such as access for bolts and other components. Universal attachment plates can be placed anywhere on the tower. The smaller wall surface area reduces the surface area exposed to wind, while the unique shape of the holes is specially designed to add strength to the tower.

All of the features of the tower contribute to giving this tower the highest strength-to-weight ratio of any temporary tower product on the market, handling requirements from simple scenarios to high strength requirements where heights exceed 70 m (230’).

The dimensions of the tower section are 2580 mm x 460 mm x 460 mm (8.46’x 18.1” x 18.1”). These particular dimensions have proven to have the most optimal strength to weight characteristics and to be the most versatile in adapting to any configuration requirement. A tower section with these dimensions is also efficiently stored, vertically in standard 20’ HC sea containers. All tower sections are exactly identical.

Each of the four corners of the tower section has a specially designed corner track that forms a continuous rail along the entire length of the tower. This allows for easy up and down travel for tools such as the gin-pole and the fall arrestor along any of the four corners, even with guy wires and insulators installed. The gin-pole is used to hoist tower sections and the fall arrestor is used to safely secure the line worker to the tower.

Material: Aluminum Alloy 6061-T6

Weight: 124 kg

Universal Attachment

The universal attachment is a component used for attaching guywires and insulators to the tower. It is placed on the outside wall of the tower, bolted to a backing plate on the inside wall, using standard 5/8” bolts (or metric equivalent). The universal attachment can be placed anywhere along the tower. When two are placed opposite to each other, the loading of guywires and insulators are transferred evenly onto the axis of the tower, which increase the overall strength of the tower. Transfer rods can be installed to connect the two opposing attachment plates, transferring the load even more directly onto the axis of the tower and reducing stress on the tower.

The innovative design of the universal attachment provides both horizontal and vertical freedom of movement for post insulators. This equalizes the unbalanced longitudinal conductor loads of adjacent spans and enables vertical inclination of the post insulator. Conductor movement is damped and forces caused by conductor movement are not transmitted to the tower.

Material: Aluminum Alloy 356-T6

Weight: 12 kg

Tower ACCESSORIES

Skywire Mount

Skywire Arm Extension

For better protection against lightning for bundle conductors and to provide the required 30 degree shielding angle for the sky wire, it is important that the skywire or earthwire is attached at a distance of at least 40 cm from the tower. Tower Solutions’ offers a skywire attachment arm for exactly this purpose.

Arm allows skywire to be offset from the tower.

Soft Soil Foundation

Insulators

- Tower Solutions supplies polymer insulators (line post and suspension) as part of the temporary tower system.

- The engineering parameters for the insulators are tailored to client specifications of the transmission lines voltages

- Depending on the load of the tower, more insulators may need to be arranged in parallel to increase the holding capacity of the assembly.

- Lower voltage insulators can also be arranged in series to form towers of higher voltages (as shown in the attached image).

- For example, 2x 150 kV insulators can be connected to form a 275 kV insulator string.

Guywires

Temporary Anchors

(Sabot)

Temporary towers can help speed up the tower erection process. While some of the line crew begins erecting the tower, others can install the permanent anchors. Temporary anchors consist of a steel sabot and 3 steel pinning rods. A soil assessment must be made to ensure that the pinning rods will hold the required loading. Typically a pionjar is used to drive these rods into the ground. Once the tower is erected, the temporary anchors can be removed because they are not needed for dismantling the tower.

Material: G 40.21-44W Galvanized steel

Weight: 9 kg

Anchors

Different types of anchors can be supplied depending on the soil conditions and requirements. Some of these are described below

HELICAL OR SCREW ANCHORS

- Made of a steel shaft with helical plates welded onto it.

- Can be screwed into the ground using a hydraulic motor.

- Holding capacity can be measured by the amount of torque applied to screw the anchor into the soil.

- Works for most classification of soils except for sand and rock.

ROCK ANCHORS

- Used along with a hydraulic hammer and drill bits.

- A hole is drilled into the rock and the anchor is placed in the hole

- The anchor is turned using the triple eye and it expands, causing it to ‘wedge’ against the rock and provide the required holding capacity.

MANTA RAY ANCHORS

Manta ray anchors are plate anchors that are driven into the soil using a hammer. The plate comes in different sizes and the holding capacity depends on the size of the plate. For the MR-1 manta ray anchor, the WORKING LOAD is a maximum of 20,000 lbs (89kN), and the ultimate capacity is a maximum of 40,000 lbs (178 kN). The advantage of these anchors primarily lies in their size (smaller and easier to transport) and their price compared to the helical anchors. However, these anchors have a lower capacity compared to the helical anchors.

Box Anchors

Box anchors replace concrete anchors in sandy areas. The advantage is that the box anchors are folded flat for storage and unfolded for use in the field. These are easy to stack and transport, and to fill while working in sand.

This means there is no lengthy process for transporting the concrete blocks.

The box anchors are opened and filled with sand. They are closed with a tarp to prevent sand loss due to wind. These have been used by SEC for ERS towers in KSA.

In addition, these anchors can be stacked to increase their holding capacity for higher voltage towers.

While the initial cost of box anchors is higher than concrete, we have estimated that the difference is saved by the client in just 1 use of the ERS. An additional advantage is that transport is swift and safer in an emergency, and the cost of transportation is greatly reduced.

Manual Installation Tools

Lineman’s Step

Fall Arrestor

Ground Rod Extractor

Pivoting Lever

Anchor Testing Device

Conductor Lifting Hook

Hydraulic Helical Anchor Installation Tools

Helical Anchor Backhoe Installation Tools

Gin-pole

The gin-pole is a tool used for raising and lowering tower sections, insulators and other components up and down the tower if other lifting equipment, such as a crane or boom truck, is not available. It is attached to any one of the four corner rails of the tower.

The gin-pole is operated manually by a small crew or by using a simple power winch or small vehicle or other pulling device. Tower Solutions offers a Capstan Winch specially designed for this purpose. Sometimes, it is difficult to get heavy lifting equipment into the working area, or it may simply be too costly, so the ginpole provides a simple way to erect the tower quickly anywhere.

The gin-pole is designed for safe and easy operation and, like all the other tower components, is completely maintenance free. The gin-pole can be locked into position at any point along the tower by securing a fixing device on its base into any of the cutout holes along the tower section.

Material: Aluminum Alloy 6061-T6

Weight: 48 kg

Rating: 250 kg (safety factor: 2.5)

Capstan Winch

The capstan winch is a petrol powered winch. It is used to raise the tower to the vertical position and to hoist and lower tower components during erection or dismantling of a tower. This winch has a unique braking system that prevents the possibility of an uncontrolled free fall and ensures easy operation when hoisting or lowering tower sections.

Maximum Capacity: 500 kg

Weight: 15 kg

Alignment Tool

Lineman’s Platform

Tower Solutions offers a fully extendible telescoping working platform that can extend from 2.5m to 4.5m to cover a range of insulator lengths at different voltages. This platform is telescopic with the inner portion completely sliding on rails into the outer portion which makes it easier to handle, stronger and safer to use. The platform comes with a safety rail and anti-skid surface. It attaches to the corner of the tower, making it rotatable up to 270 degrees and allowing more flexibility to install conductors for tension towers in one platform position.

Lineman’s Step

When climbing the tower, the lineman uses the holes in the tower walls for a ladder, and the hard soles of his boots are rigid enough that climbing is comfortable. Sometimes though, it may be necessary for the climber to spend more time in one place, in which case it would be more comfortable to rest the foot on a wider surface. The lineman’s step provides a convenient platform for this purpose, and is easy to carry along on the climber’s belt.

Fall Arrestor

The fall arrestor is a safety device for the lineman. Designed exclusively for Tower Solutions, this device allows free movement in the upward direction and only in the upward direction. Like a seatbelt in a car, it locks into position when pulled in the opposite direction. As the line worker climbs the tower, the fall arrestor travels effortlessly with him, attached to any one of the 4 corners of the tower. But when climbing down, the fall arrestor has to be moved by the lineman. In the event of a fall, this device locks firmly onto the fixed rail and stops the fall before it starts. The free upward movement of this safety device eliminates the need for manual locking mechanisms and makes climbing the tower easier, faster and safer.

Material: Aluminum Alloy 6061-T6, SS/304

Rating: 140 kg (safety factor: 3, Fall Arrester Testing report by Tower Solutions Inc., January 25, 2005; IEC tested in Brazil)

Ground Rod Extractor

The ground rod extractor is a tool used for removing the steel pinning rods from the ground. Once the tower has been erected and securely guyed to permanent anchors, there is no further need for the temporary anchors and they should be removed. And after the tower has done its job and has been dismantled, the foundation plate must be removed from the ground. The ground rod extractor is needed to pull the rods out of the ground so the anchors and the foundation plate can be removed.

Maximum Capacity: G 40.21-44W Steel

Weight: 15 kg

Pivoting Lever

(Bayonet, Rotating Gin Pole)

Anchor Testing Device

Anchor holding capacity is critical for an ERS design. Tower Solutions offers an anchor testing device to test the capacity of anchors in any soil condition. This is important particularly when using anchors such as manta ray or plate anchors, as this is the only way to ensure that your anchor can hold the necessary load on the tower.

Conductor Lifting Hook

Hydraulic Helical Anchor Installation Tools

This method includes an 18 HP hydraulic motor, 4 hydraulic hoses with quick-disconnect couplers, a hand control pedal with a PSI meter, a rotating hydraulic drive head, and a steel torque bar.

This is the most common type of installation method used by Tower Solutions’ clients around the world. This method has the advantage of portability; the equipment is easily transported to hard-to-reach locations.

Helical Anchor Backhoe Installation Tools

Transfer Rods

CRANE/Boom INSTALLATION ACCESSORIES

Crane/Boom

Sections can be assembled on the ground using the standard tools above and lifted into spot using a crane. This saves valuable time during installation because the entire tower can be assembled on the ground, allowing it to be raised in a few minutes. Different types of cranes or boom trucks can be used. This method is suitable for installations where there is space and easy availability of heavy equipment.

HELICOPTER INSTALLATION ACCESSORIES

Helicopter Centering Device

The Helicopter Centering Tool is a cone-shaped tool designed to assist a helicopter when installing tower sections onto the top of a tower under erection The Helicopter Centering Tool is installed onto the bottom end of the tower section being lifted by the helicopter. This tool will assist the helicopter pilot in aligning the bottom of the tower section onto the tower upon which it will be lowered.

Material: Aluminum Alloy 6061-T6

Weight: 11 kg (24 lb)

Configurations

You can adapt the Tower Solutions system to many physical configurations:

- Suspension tower in Delta configuration

- Suspension tower in Running Angle configuration

- Anchor tower (for line angle between 30° and 60°)

- Dead End tower (for angle >60°)

- Chainette (for small angles)