Advantages

The Tower Solutions tower is in a class by itself. This tower sets a new high quality standard for emergency response to tranmsission line problems and for the tools that are used to deal with the emergency. Some of the advantages of the Tower Solutions tower are discussed below.

Best In Business

Tower Solutions stands behind its product with a 10 year warranty, which is the best in the industry. A number of product features make the Tower Solutions tower more functional, stronger, and lighter than any tower on the market. The Tower Solutions tower is fully accredited to IEEE standards as well as to IEC.

Completely Tested

The Tower Solutions tower is the only tower system to comply with BOTH the North American IEEE 1070-2006(Guide for the Design and Testing of Transmission Modular Restoration Structure Components) as well as IEC 60652 (Loading Tests on Overhead Line Structures).

IEEE standards require that the components of the tower are tested, in isolation, on a test bench. This ensures that each component performs as to design specifications. This testing does not take into account the performance of the complete tower working as a whole, in real life conditions. Tower Solutions’ tower components successfully pass all IEEE test requirements.

IEC standards require that the complete tower is tested as a whole, in real field conditions. Tower Solutions’ tower successfully passes this tough test under very rugged conditions. This test imposes a more realistic representation of a tower performing in actual service. For one particular client, this testwas pushed to 200% of the client load requirement, with the tower passing flawlessly at a loading of 160,400 N. No other restoration tower on the market can make this claim.

Our manufacturing QC process randomly selects samples of all components for ongoing testing in accordance with IEEE standards. Clients are always invited to witness the tests.

Foundation for Soft Soils

Tower Solutions offers an expandable base that can be expanded by a factor of 4 to 9 times the size of the standard base. This spreads the load and makes it possible to erect the tower on soft ground.

Articulation

The articulating base has a special bronze alloy component to reduce friction on the weight-bearing surface at the base of the tower. During tower erection, the low friction surface makes the pivoting action of the tower around the ball smoother and makes tower erection easier. During storage, the low friction surface prevents corrosion and metal bonding due to oxidation.

The articulating base is designed to rotate a full 360 degrees. This makes it possible to align the tower in any direction, which means that the tower can be positioned on any convenient underlying terrain and inclination, without being restricted by the direction of the conductors.

At 120 Kg, the articulation is light enough to be easily carried by the work crew. Standard 5/8”steel rods secure the pivoting plate to the cone for transport and storage. These steel rods are located directly on the cone and out of the way, which makes the base a little easier to store, while providing step-ups for the lineworker to begin climbing the tower. The cone of the articulating base is attached to the foundation plate by means of a flange plate which raises the bolting arrangement off the ground and away from the underside of the plate, as well as avoiding the need for special bolt protectors.

Tower Section

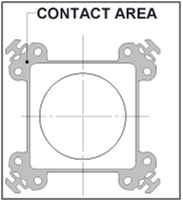

One of the most important features of a temporary tower is its physical strength. In the case of the modular tower, Tower Solutions has a large surface area of contact between the tower sections. This is a critically important factor in any tower construction. With dimensions of 460mm x 460mm, not only is the overall dimension larger, but the wall is also thicker. The increased cross-section results in greater mechanical strength, which means less chance of buckling or bending. A structural analysis can quickly confirm the importance of this and its effect on increasing the moment of inertia.

Higher strength means a number of things, such as

- more versatility

- fewer guywires

- tower can be higher

- can support longer spans

- can stand up to stronger winds

Cross-Section

Since the end blocks of each tower section are flush with the ends of the sections, the surface area of contact between two sections is greater. A larger surface is very important when the tower is in bending mode or buckling mode and the load is distributed over a larger surface.

Squareness of the Tower Section

Tower Solutions tower sections are fabricated using the highest precision NC machining technology available, with tolerances in the thousandths of a millimeter. This means that adjacent tower sections will align squarely, with no deflection from section to section. The tower will be perfectly straight and true.